Electric versus Air driven boosters

Posted by Chris Ashworth, Chief Engineer on Mon, July 13, 2020

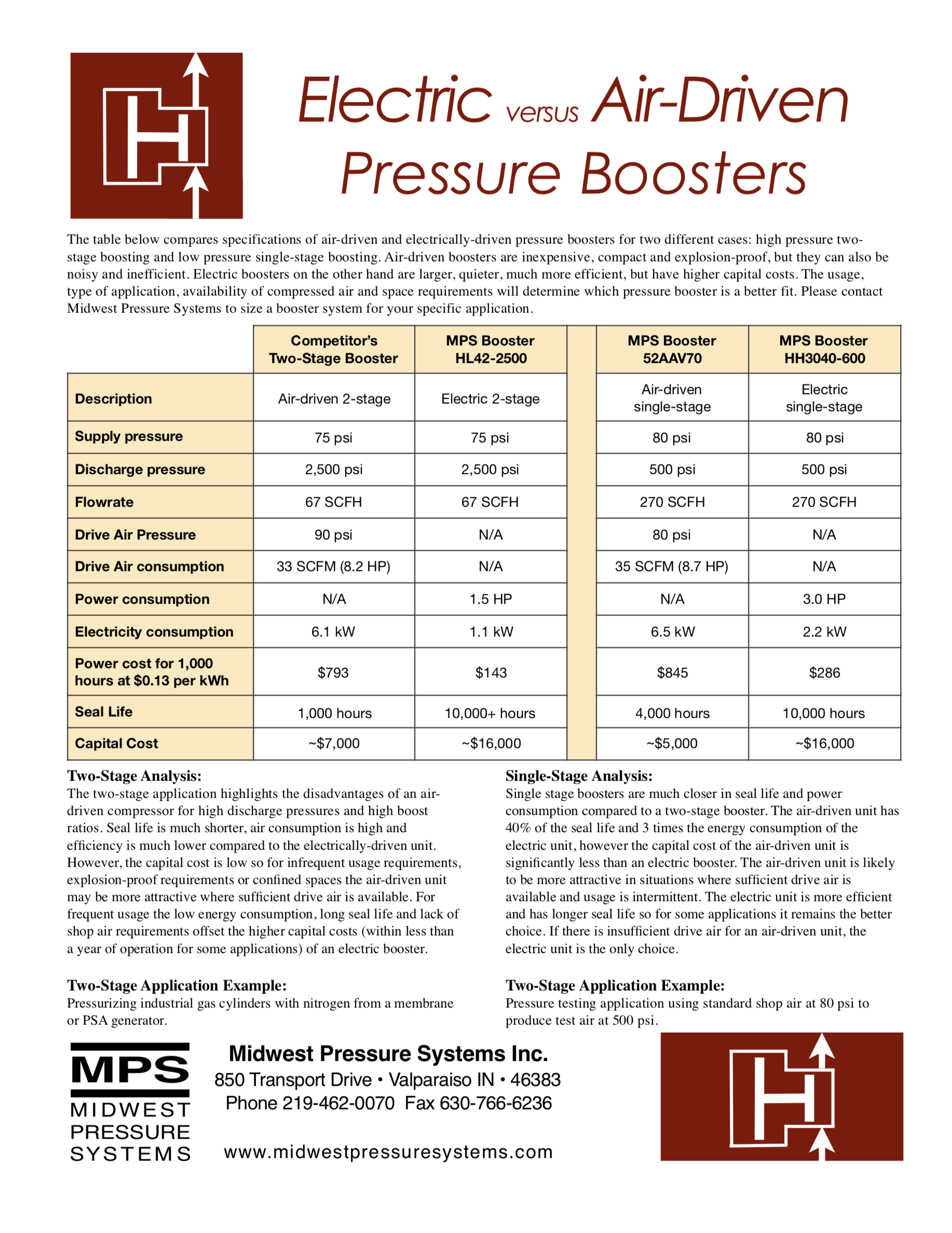

The link to the article below compares specifications of air-driven and electrically-driven pressure boosters for two different cases: high pressure two-stage boosting and low pressure single-stage boosting. Air-driven boosters are inexpensive, compact and explosion-proof, but they can also be noisy and inefficient. Electric boosters on the other hand are larger, quieter, much more efficient, but have higher capital costs. The usage, type of application, availability of compressed air and space requirements will determine which pressure booster is a better fit. Please contact Midwest Pressure Systems to size a booster system for your specific application.

Electric Air and Gas Boosters, More Models, More Flow

Posted by Chris Ashworth, Chief Engineer on Mon, May 4, 2020

Midwest Pressure Systems has expanded its electrically-powered air and gas pressure boosters for higher flow rates with pressures up to 650 psi. From an 80 psi supply pressure Model HL2540 will deliver deliver 2.5 scfm of air or gas at 450 psi and Model HL3040 will deliver deliver 1.9 scfm of air or gas at 650 psi. These booster compressors are economical, non-lubricated, single-stage and air-cooled. They can operate 10,000 hours, 24 hours a day, 7 days a week with no maintenance. Both models are driven by a 1.5 horsepower, 110 VAC hydraulic power unit.

Electrically-Driven Air and Gas Booster Compressor

Posted by Chris Ashworth, Chief Engineer on Fri, Oct 25, 2019

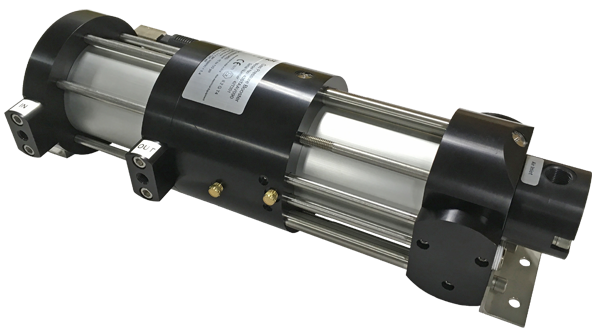

Midwest Pressure Systems introduces Model HL42, an economical, noncontaminating, two-stage, air and gas booster compressor. It is non-lubricated and driven by a 1.5 horsepower, 110 VAC hydraulic power unit. It will deliver 1.2 scfm of gas at 2500 psi from an 80 psi supply and operate for over 10,000 hours, 24 hours a day and 7 days a week with no maintenance.

Next Generation 10:1 ratio booster

Posted by Chris Ashworth, Mechanical Engineer on Wed, February 21, 2018

Midwest Pressure Systems has retired the current 10:1 ratio booster, model 4125AAV83, and replaced it with the next generation 10:1 ratio booster, model 420TAAV090. The 420TAAV090 is a two stage booster capable of discharge pressures as high as 1,305 psi (90 bar). Improvements in the new design included longer operating life, higher flow rates, higher volumetric efficiencies and higher maximum discharge pressures. The 420TAAV090 was designed to bolt into the same mounting location as the 4125AAV83. The drive air and boost gas ports are in different locations so piping modification will be necessary if the intention is to replace the 4125AAV83 with a 420TAAV090 booster.

420TAAV090 air booster information

420TAAV090 gas booster information

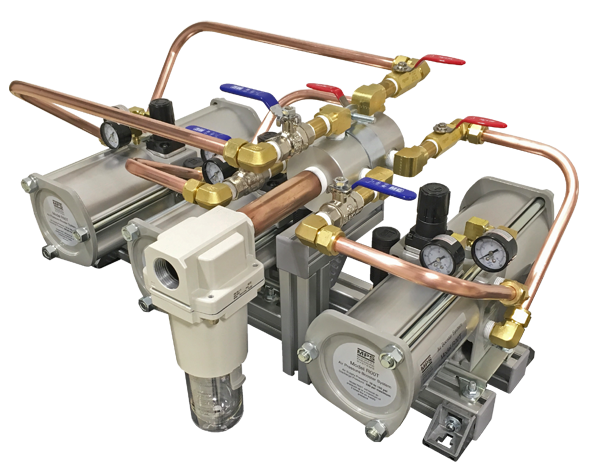

R00T Air Booster System Launch

Posted by Chris Ashworth, Mechanical Engineer on Fri, December 29, 2017

MPS is proud to release the R00T. The R00T is a compact triple booster system for applications that require a large receiver tank or the customer already has a larger receiver tank on site. The R00T can be mounted to the large receiver tank platform or near the receiver tank. MPS recommends 3/4� or greater piping. The R00T is designed for flow rates between 50 SCFM to 150 SCFM and compressed air pressure boosts between 20 psi to 100 psi.

"50" Series Air and Nitrogen Boosters Available

Posted by Chris Ashworth, Mechanical Engineer on Tues, August 15, 2017

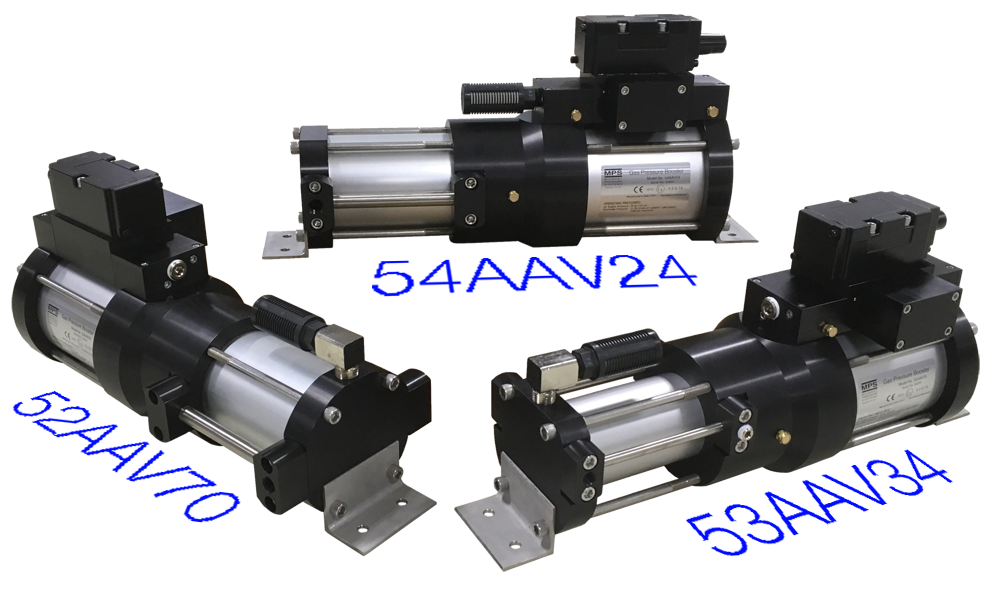

MPS is proud to release the "50" series boosters. Requests for booster systems with higher flow or higher boost ratios have resulted in the design of a 5 inch drive section. The 5 inch drive connects to MPS standard 4 inch, 3 inch and 2 inch boost sections. A "50" series boost ratio is increased by over 50% compared to the standard "40" series. The higher boost ratio allows the "50" series booster to provide higher flow rates at given pressures compared to the four inch drive units.

"50" Series models available now for boosting Air or Gas

- 52AAV70 with a 7.2:1 boost ratio from 0-10 scfm

- 53AAV34 with a 3.7:1 boost ratio from 0-24 scfm

- 54AAV24 with a 2.5:1 boost ratio from 0-40 scfm

"50" Series Air booster information

"50" Series Gas booster information

How to Increase Compressed Air Pressure

Posted by Chris Ashworth, Mechanical Engineer on Mon, February 6, 2017

Factories, plants and shops can have inadequate compressed air pressure for a variety of reasons such as line pressure drop, equipment requiring higher pressure than standard compressed air pressure and high local demand. MPS boosters can be installed at the point of use and provide an increase in pressure anywhere from 5 psi to 1000 psi. This allows companies to operate with their standard compressed air throughout the factory but at certain locations a booster can be utilized to provide the required higher air pressure. MPS boosters are commonly used with plasma cutters, nitrogen generators, pneumatic air tools, pneumatic cylinders, high pressure test stations, and more.

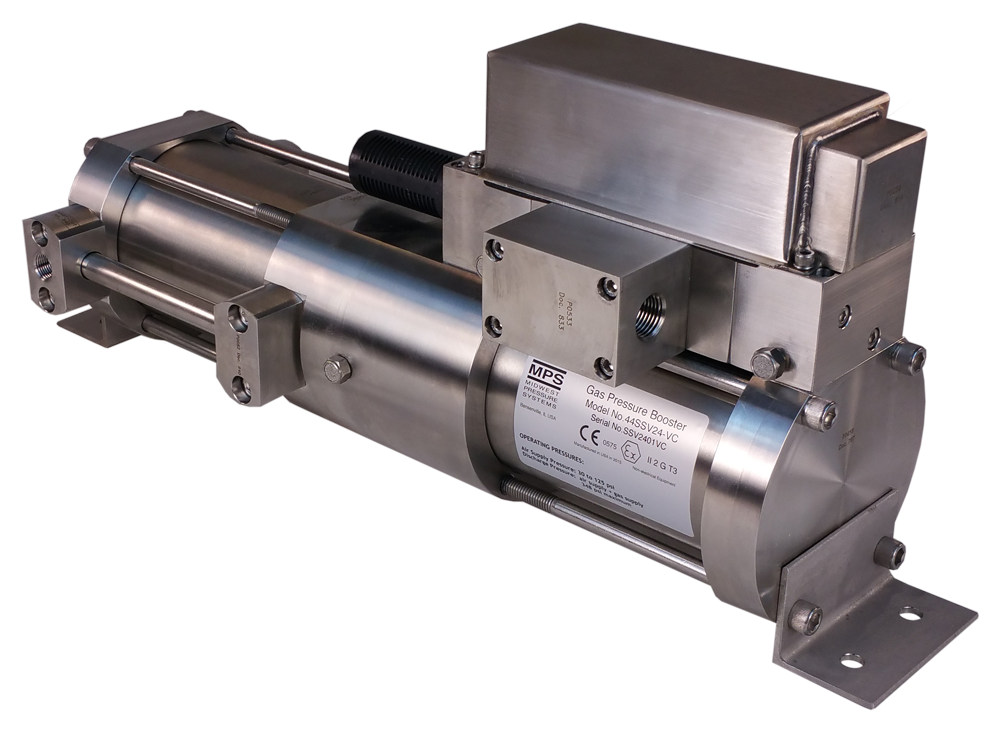

316 Stainless Steel Air or Nitrogen Pressure Boosters

Posted by Bob Vogt, Chief Engineer on Tues, March 8, 2016

Midwest Pressure Systems has added stainless steel 2:1 ratio, 2.78:1 ratio and 4:1 ratio air or nitrogen pressure boosters to its extensive product line of air pressure boosting equipment. Our new Models 44SSV24-VC, 43SSV34 and 42SSV48 meets the material requirements of offshore oil and gas facilities, chemical plants with corrosive environments and food industry wash down requirements.

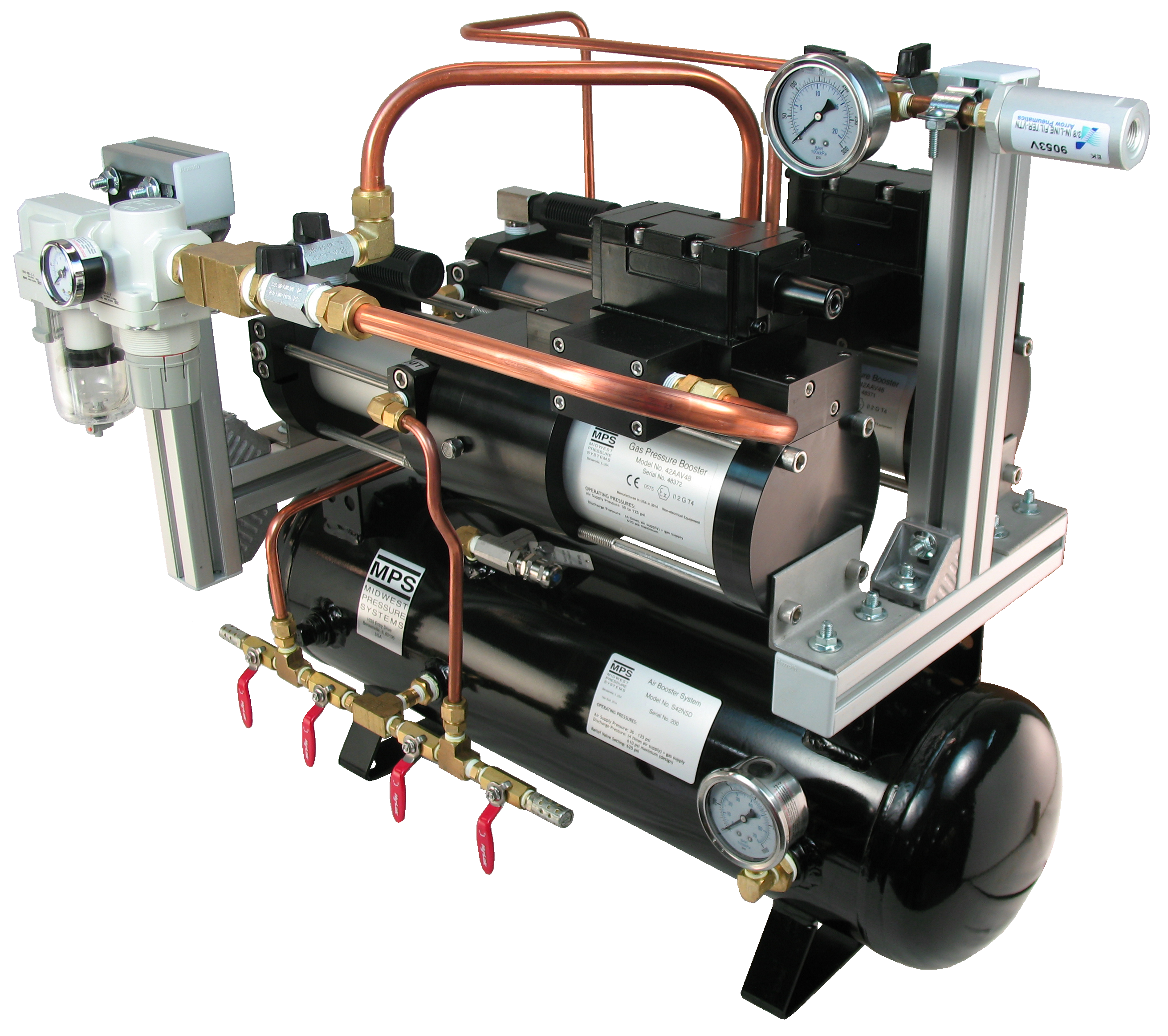

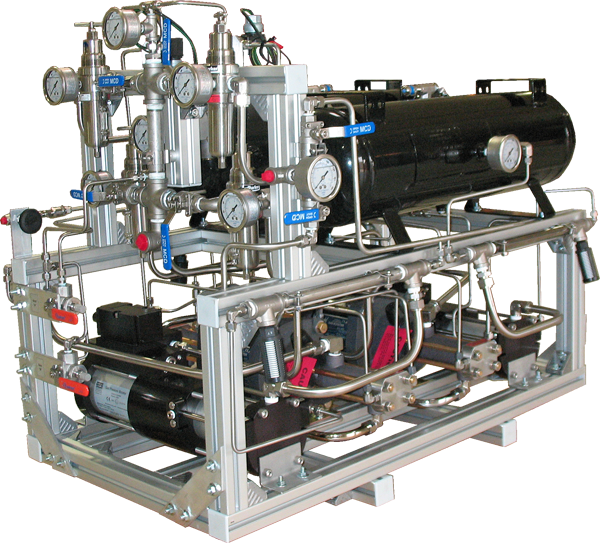

Custom Stainless Nitrogen Booster System

Posted by John Riordan, Mechanical Engineer and Spencer Kost on Tues, July 14, 2015

Midwest Pressure Systems recently completed a custom two-stage nitrogen pressure booster system capable of achieving a 33:1 pressure boost. The system uses two 5:1 nitrogen boosters which discharge into two 5.5 gallon ASME tanks that provide the supply for two 30:1 boosters. The system has built in redundancy to allow one set of boosters to be isolated and continue functioning during maintenance of the other set. The system was engineered with stainless steel components, and required approximately 75 feet of 316 seamless stainless steel tubing of various sizes and pressure ratings.

The system operates at pressures up to 2,200 psi and 3.2 SCFM flowrate with supply nitrogen pressure of 85 psi and drive air pressure of only 60 psi. An electronic pressure switch automatically closes the pilot valves, stalling the final stage boosters when a desired output pressure is reached.

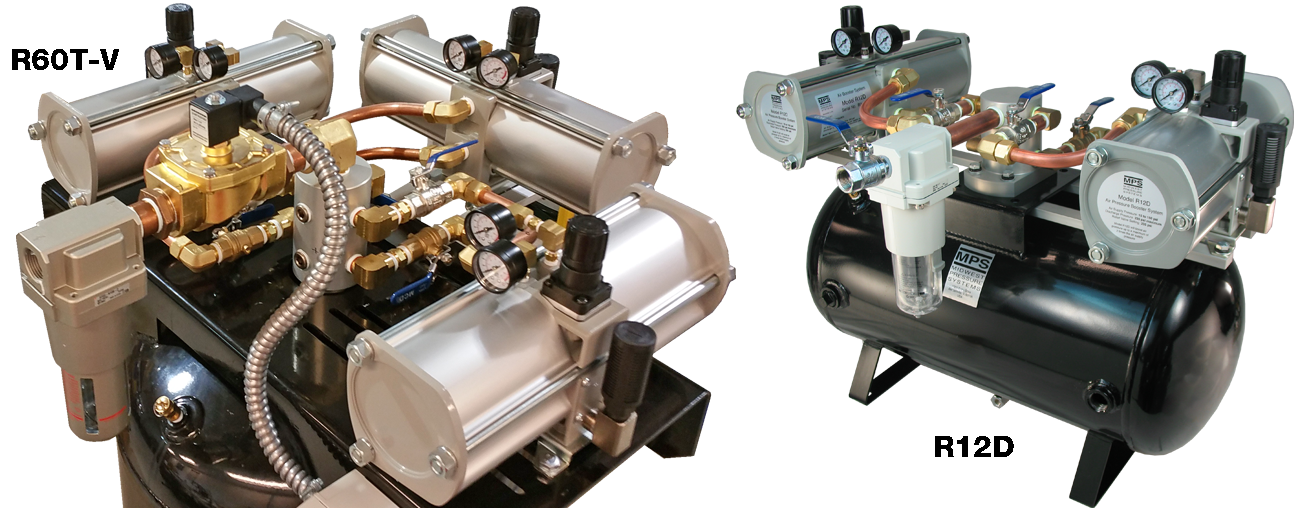

Multi-Booster Design Enhancement (Air Boosters)

Posted by Chris Ashworth, Mechanical Engineer on Mon, May 4, 2015

Midwest Pressure Systems has improved the design of our multi-booster air systems by making them more compact while simplifying the assembly and maintenance process. The photos below of an R60T-V (with optional solenoid shutoff valve) and an R12D illustrate the new design. All multi-booster systems are able to operate with one booster (all other boosters are on "Stand-by") or with multiple boosters operating simultaneously.

New Standard Product - High Flow Dual Booster System (S42N5D)

Posted by Matt Marino, Mechanical Engineer on Tues, December 2, 2014

Midwest Pressure Systems expands its product line with the new S42N5D high flow dual booster system. The S42N5D features two 5:1 ratio boosters mounted on a 5.5 gallon ASME receiver tank, and can produce flow rates of up to 16 SCFM. This system has the capability of operating one or both boosters using a system of ball valves. The system is designed to allow for one booster to be isolated and removed for maintenance, or placed in a stand-by mode when higher flow rates are not required. This redundancy feature eliminates process downtime.

Gas Booster - Functional Animation

Post Updated by Aaron Sebby, Assembly Manager on Mon, July 28, 2014

As a service to our engineering audience and customers, a brief animation has been created to show how our Gas Booster functions. Pay close attention to how the control valve, pilot valves and check valves work in concert with air pressure input to amplify the pressure of air, nitrogen, natural gas, oxygen and any inert gases. Please call if you need further information on how our products can be used for your application.

PLC Controlled High Pressure Dual Nitrogen Booster System

Posted by Matt Marino and John Riordan, Mechanical Engineers on Wed, April 16, 2014

Midwest Pressure Systems, Inc. has further developed its Programmable Logic Controller (PLC) controlled nitrogen booster systems to include dual booster systems that operate in series (pictured below). This configuration enables the systems to operate with discharge pressures in excess of 500 psi and flow rates of approximately 2 SCFM. The PLC controls the valve sequencing in order to deliver the desired flow rate and discharge pressure. PLC controlled booster systems maintain nitrogen purity and are used with bulk, desiccant, and membrane nitrogen generators.

Gas Pressure Booster - Expanded Product Line: 44AAV24

Posted by Aaron Sebby, Assembly Manager on Mon, November 25, 2013

Applications with high flow rates and nominal increses in pressure are becoming more common (e.g. vapor recovery, nitrogen boosting, plasma cutting, etc.). Midwest Pressure Systems, Inc. has launched the 44AAV24 nitrogen booster to better service these requirements. The 44AAV24 booster was designed with a four inch diameter boost piston and a four inch diameter drive air piston to yield a boost ratio of 2:1 with flow rates of up to 20 SCFM and pressures as high as 348 psi (24 bar). The 44AAV24 can be used to boost pressures of nitrogen, shop air or other inert gases.

PLC Controlled Dual Nitrogen Booster System

Posted by Chris Ashworth, Mechanical Engineer on Thurs, August 1, 2013

Midwest Pressure Systems, Inc. has expanded its Programmable Logic Controller (PLC) controlled nitrogen booster systems product line to include dual booster systems that operate in parallel (shown below). The new systems can deliver pressures as high as 500 psi and flow rates as high as 30 SCFM. PLC controlled booster systems maintain nitrogen purity and are used with bulk, desiccant, and membrane nitrogen generators. The PLC triggers the system in accordance with the programmed instructions.

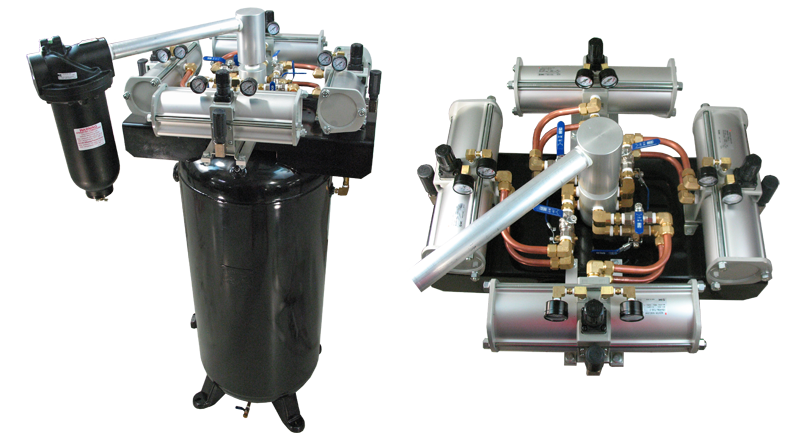

Redundant High Flow Air Pressure Booster System (R60Q)

Posted by Chris Ashworth, Mechanical Engineer on Wed, June 5, 2013

In November of 2012, Midwest Pressure Systems (MPS) launched our Model R60Q air pressure booster system with four boosters mounted on a 60 gallon receiver tank. One set of two boosters delivers up to 100 scfm of high pressure air while the other set is in stand-by mode. Closing two ball valves idles the operating set of boosters and opening two other ball valves activates the standby set. To eliminate downtime the idle set is isolated from the pressurized system by the switchover valves. It can be safely removed for maintenance while the operating set remains active. The system is also designed to enable all four boosters to operate at the same time.

Air Filter & Regulator Improvement

Posted by Kevin Malgapu, Assembly Specialist on Wed, June 5, 2013

Starting in 2013, Midwest Pressure Systems (MPS) air booster systems are using new and enhanced inlet air filters and pressure regulators. The new filter bowls are completely transparent (for better viewing of condensate), more compact and easier to replace. For increased efficiency, the new pressure regulators have a much lower pressure drop than the previous models.