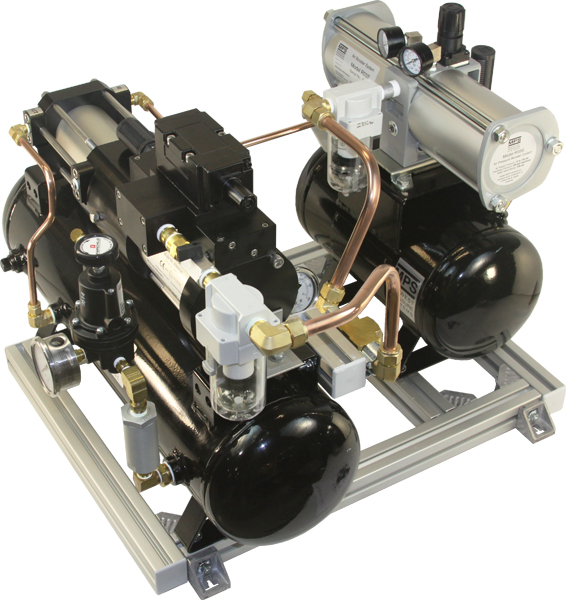

R43A35 Air Booster System

4 to 1 Boost Ratio, 0-30 scfm Flowrate

This two stage, shop air pressure booster system uses shop air to boost the pressure of a separate air stream. The maximum discharge pressure is 4 times the shop air supply pressure. Flowrate information will be available soon.

Construction

The first stage booster is a 2:1 booster with a built-in pressure regulator. The major components of the second stage (2.78:1) air booster are anodized aluminum. The hardware components, check valves and piston rod are stainless steel. The drive cylinder and boost cylinder are seperated by a distance piece with a vent port which prevents cross contamination between the shop air and the boost air. The booster is non-lubricated, and uses filled Teflon® piston seals and rod seals. It requires no electricity, cooling water, or air-line lubricator and is explosion proof.

Operation

The system discharge regulator located at the outlet of the second stage tank can control discharge pressures between 5 and 400 psig. The flowrate and discharge pressure from the 1st stage booster can also be controlled by using the built-in regulator. When there is no demand for high pressure air, the system will stall when it reaches the maximum discharge pressure. When there is a need for high pressure air the pressure in the discharge line drops, and causes the system to restart automatically.

»Frequently Asked Questions - FAQs

»Shipping Information

»Air Booster Repair Kits

Two Stage, 4:1, Dual Air Booster System

3.5 and 5.5 Gallon Tanks

Model R43A35 • $10,600

- Two Stage, 4:1, Dual Air Booster System

- 400 psi Maximum Discharge Pressure

- 3.5 Gallon Receiver Tank (Stage 1)

- 5.5 Gallon Receiver Tank (Stage 2)

- Drive Air Regulator

- High Flow Discharge Regulator

- 29"(L) x 31.1"(W) x 22.4"(H) • 150 pounds

3D Model is available - contact us

» Brochure

View more products:

Air Pressure Booster Systems

• Gas Pressure Booster Systems

• Electric Inert Gas Pressure Booster Systems

• Repair Parts & Kits

• High Pressure Tanks